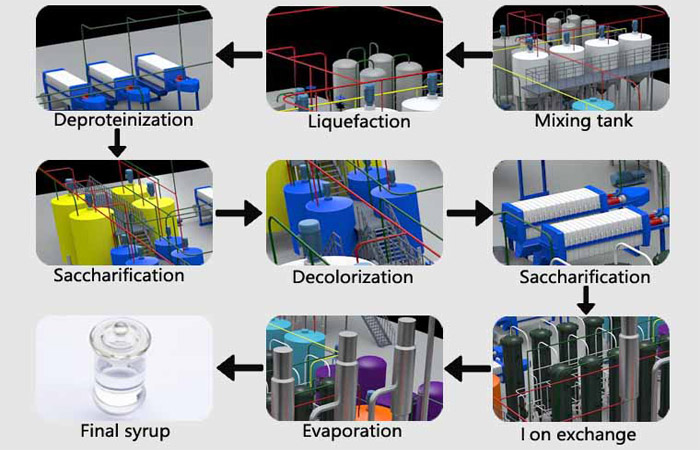

syrup manufacturing process flow chart

syrup manufacturing process flow chart-high fructose corn syrup manufacturing process

High fructose syrup production is according to the starch processed by enzymatic method to get saccharification liquid, then part of glucose processed by isomerism system change to fructose, that is to say the high fructose syrup is a mixture of glucose and fructose. In the industrial high fructose syrup production, to get more sweetness high fructose syrup, usually filter the glucose, then make isomerism process repeatedly to change more glucose into fructose, impove the fructose content. High fructose syrup can substitute sugar to used in food and beverage industry, with more advantages, the cost is lower than sugar, but flavor and taste is better. High fructose syrup production process is: mixing and liquidation - saccharify - liquid syrup decolorizing - filtration - ion exchange - isomerism system - syrup refined - F42 high fructose syrup.It's worth to say that if you don't need the final syrup is transparent, no need the decolorizing process.

high fructose syrup production adopted dry milling method to get the high fructose syrup production raw material - corn flour, totally process no pollution water discharge. The low fat corn flour after mixing with water and adjust the liquid concentration, delivery for liquefaction section, after high temperature liquidation, under starch enzymes catalysis, the starch liquid change to dextrin, then the saccharify enzymes catalyze the dextrin to get glucose, next glucose processed by isomerism system, to get high fructose syrup.

High fructose syrup production detaills:

1. Mixing and liquefying process: mixing the corn flour / starch(or other raw material) with water, adjust the PH value to 5.0-6.0, after mixing add liquifying enzyme, equipped with ejector to complete the liquefaction process. Then we can get a suitable liquid can be prepared for glycosylated.

2. Saccharify: use saccharifying enzymes, processed the liquid temperature to 58-60 degree, after reach the request DE value can get into next process. Saccharify process performance decided the high fructose syrup production effect.

3. Liquid glucose decolorizing: uses second time decolorizing process to get bright syrup. This production process adopted plate and frame filter press machine to complete.

4. Filtration: this process adopt drum filter to remove soluble protein, decrease the protein content in glucose liquid.

5. Ion exchange system during high fructose syrup production: adjust the temperature and PH value, remove irons, salt and ash, get pure syrup.

6. Concentration: under vacuum condation to make heating and evaporation, make the syrup concentration meet the standards, after the temperature reduce, pump into next manufacturing process.

glucose corn syrup processing lRead More

glucose syrup production plant from cassava pdf,glucose corn syrup processing line,glucose syrup making machine,production of glucose syrup f...

Introduction of Glucose syrup dRead More

Glucose syrup also known as confectioner's glucose, is a syrup made from the hydrolysis of starch. Glucose also is called starch sugar. Maize...

Annual capacity 50,000tons gluc

Annual capacity 50,000tons glucose syrup production plant, this capacity project our company totally installed three. Recently, we complete the third that is the newest glucose syrup production plant project

Read More

Daily production of 100 tons ma

This corn syrup production plant project all equipments design, manufacturer and delivery made by SIDA Company, with corn processing annual capacity 10 million tons, the corn syrup production capacity 8 million tons. Manufactured for our Nig

Read More

Phone669

Phone669

hoan366@hotmail.com

hoan366@hotmail.com