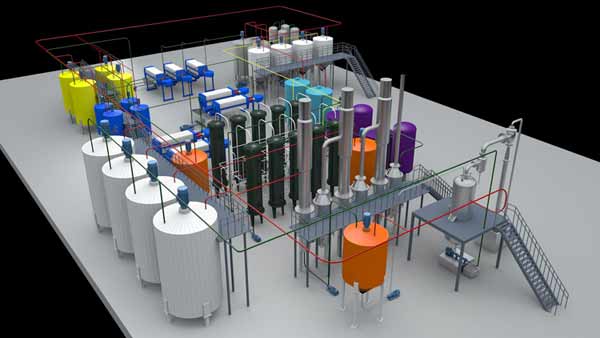

Syrup Processing Line

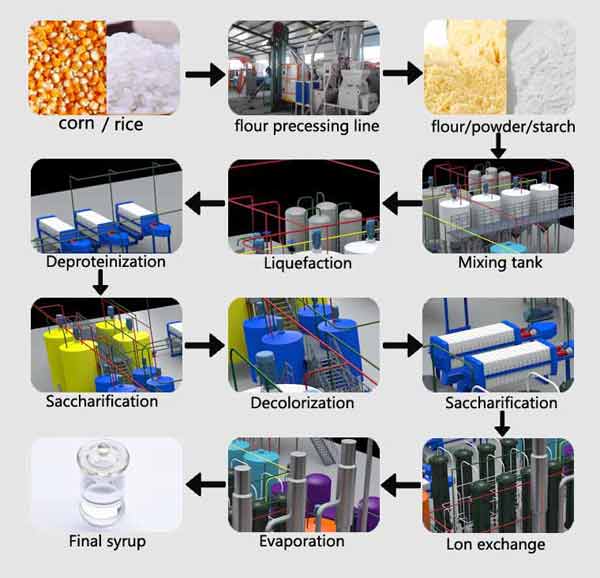

Styrup production machine flow process chart

Manufacturer by AMM Company, about syrup processing machine, we can offer:

1. Complete set energy saving syrup production equipment, according to client's different demands offer personal production plan, we will design the most ecnomic benefit and high efficiency technical plan for you.

2. Automatic control system: the advanced nature of control system is the guarantee of high quality products of syrup production. Continuous and stable production can reduce the production cost.

3. syrup production plant installation, adjust and operation training: all equipments through strict quality testing, after the test passes, Doing Company engineer will adjust the equipments and train the operation people, make sure the production technology reach the requests and your syrup production operation smoothly.

syrup processing line flow chart

High fructose syrup production detaills:

1. Mixing and liquefying process: mixing the corn flour / starch(or other raw material) with water, adjust the PH value to 5.0-6.0, after mixing add liquifying enzyme, equipped with ejector to complete the liquefaction process. Then we can get a suitable liquid can be prepared for glycosylated.

2. Saccharify: use saccharifying enzymes, processed the liquid temperature to 58-60 degree, after reach the request DE value can get into next process. Saccharify process performance decided the high fructose syrup production effect.

3. Liquid glucose decolorizing: uses second time decolorizing process to get bright syrup. This production process adopted plate and frame filter press machine to complete.

4. Filtration: this process adopt drum filter to remove soluble protein, decrease the protein content in glucose liquid.

5. Ion exchange system during high fructose syrup production: adjust the temperature and PH value, remove irons, salt and ash, get pure syrup.

6. Concentration: under vacuum condation to make heating and evaporation, make the syrup concentration meet the standards, after the temperature reduce, pump into next manufacturing process.

7. Isomerism process: this process function is change the glucose into fructose. More changed percentage, more sweetness.

8. High fructose syrup refining process: the isomerized raw syrup was prepared by the secondary decoloration and the secondary concentration process. After adjusting the temperature, it was pumped into the special tank for storage, which was the finished product F42 high fructose syrup.Above all, this is our Company high fructose syrup production, the main equipments is: high temperature ejector, ion exchange column, tanks, evaporator, filter press.

glucose syrup making machine technology process for you:

1. Mixing and liquefaction:Mixing slurry: Add thermostable a-enzyme and water to starch, and mix them in mixing slurry tank, get a suitable slurry which is transparent and sticky. Spray liquefaction: Heating all tanks by steam, then open liquid ejectors and pumps, deliver material continuously and evenly, and control flow by production capacity. Flash evaporate material in Laminar flow tank, and keep temperature, observe liquefaction effect. After this liquefaction step processed by our glucose syrup making machine, adust the PH value to 4.4-4.5, then it can be prepared for glycosylated/ saccharification.High temperature treatment: Send passed material to the second Liquid ejector, and keep temperature. Carry slurry to buffer tank by pump. Mixing and iquefaction process is the first step of glucose syrup making machine.

2. Filtration section during the glucose syrup making machine:Filter protein and slag by Plate-and-frame filter press machine.Carry away protein and slag by bottom slot. This is an add-value in your plant if you adopt our glucose syrup making machine, because the starch contain many protein, after filter, the protein cake will be a good source for animal feed.

Syrup inflow buffer tanks, then be sent to next step by pump.

3. Saccharification:Cooling syrup by Heat-exchanger, then send them to Saccharification tank (mixer and coil pipe are set in saccharification tank) by pumps, then add glucoamylase.

4. Decolorization by glucose syrup making machine:Carry passed syrup into decolorization tanks(mixer and coil pipe are set in saccharification tank) by pump. Decolor by activated carbon added.

5. Filtration process/ decarburization:Filter waste activated carbon by plate-and-frame filter press machine. Unclean syrup is sent to big buffer tanks by pump.Carry clean syrup into buffer tanks during our glucose syrup making machine process.

6. Ion exchange section:Carry syrup into ion exchange columns. Resin clean syrup in ion exchange columns. Then carry clean syrup into buffer tanks. When resin loses effect of our glucose syrup making machine, stop carry syrup into Ion exchange columns, and change another Ion exchange column for work. Recover Resin: Using heat water to bush resin, then use acid fluid, and alkali fluid to bush Ion exchange columns till resin has function.

7. Evaporation:Evaporate syrup by Triple-concentrate of evaporator and Single-concentrate of evaporator. When syrup concentration is OK, shut down steam and stop evaporation. And carry syrup to storage tanks by pumps. You can click syrup evaporator to learn more details of our machine.

Maltose syrup process machine technology description:

1. Mixing slurry unit during the maltose syrup process:Put the rice powder and water into the mixing tank, then put the enzyme, keep on particular standard temperature, waiting the starch reaction for some time, then can be transported to next work section.

2. Ejector liquefaction unit:The mixed rice pwoder milk is sent to buffer tank then liquefied by ejector(also named jet cooker) with the aid of enzyme at high temperature in regular time for maltose syrup process.

3. Filter press deproteinization:Because of inside the rice slurry still have too much protein, so the slurry need to pumping into the press filter, after press the slurry, the syrup will flow into the slot, then the protein will stay inside the filter machine. Usually adopt the plate frame filter press machine for maltose syrup process, and after this process, there will be many protein cake can be sale as animal feed.

4. Saccharification:The liquefied material is sent to enzyme saccharification tank for reaction. Maintain at specific temperature for some time, the syrup will transfer to maltose syrup, this saccharification process is important for the quality of matose syrup process.

5. Decolorization:After LAB testing, all the maltose syrup pumping into the decoloration tanks, at uniform temperature, mix with activated carbon, usually it have to make twice to get pure and colorless maltose syrup.

glucose corn syrup processing lRead More

glucose syrup production plant from cassava pdf,glucose corn syrup processing line,glucose syrup making machine,production of glucose syrup f...

Introduction of Glucose syrup dRead More

Glucose syrup also known as confectioner's glucose, is a syrup made from the hydrolysis of starch. Glucose also is called starch sugar. Maize...

Annual capacity 50,000tons gluc

Annual capacity 50,000tons glucose syrup production plant, this capacity project our company totally installed three. Recently, we complete the third that is the newest glucose syrup production plant project

Read More

Daily production of 100 tons ma

This corn syrup production plant project all equipments design, manufacturer and delivery made by SIDA Company, with corn processing annual capacity 10 million tons, the corn syrup production capacity 8 million tons. Manufactured for our Nig

Read More

Phone669

Phone669

hoan366@hotmail.com

hoan366@hotmail.com