sida how to make glucose syrup_how to make syrup

For durable glucose syrup processing equipment professional corn glucose syrup machine, it is enviroment friendly, no pollution. We apply dry method to transfer corn and rice flour into syrup. Since 1988, we begin to do research. We can produce high quality syrup products.

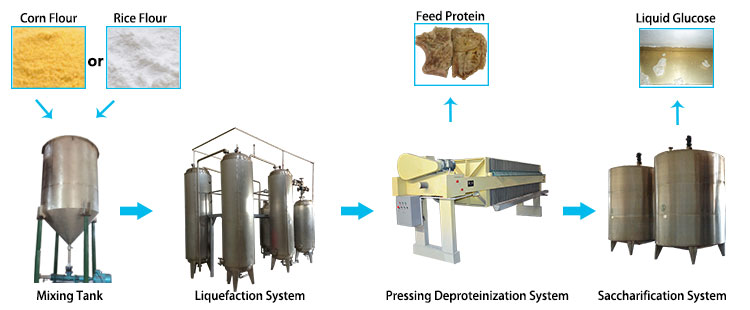

Mixing and saccharification system

1-a). The function of mixing tank is to get right density of the slurry, the water is very important at this time. Normally we use warm water, the temperature is about 50-60 degrees. And add amylase and PH reagent with mixing.

1-b). For liquefaction system,the temperature is very important. If temperature is too high the flour will be cooked. When the materials go into the first liquid ejector, the temperature should be 120 degrees. Then goes into pressure tank, and flow into four laminar flow tanks, finally go out from maintaining tank. This tank connected with another liquid ejector. The temperature should be 108 degrees. The time between these procession is about 90 minutes. Then the materials go into transfer tank. The mainly usages of transfer tank are:

1. if the liquefaction is not finished, we can put all the materials into liquefaction system again.

2. to make preparation of pressing.

1-c). Press filter is the parts to take all the protein out, at 70 - 80 degree Celsius will be very efficiency.

We use air compressor to increase the pressure. When we finished the pressing, we can use water cannon to clean these machine.

1-d) After the pressing, the materials go into saccharification tank. But before entering, we will use a heat-exchanger to make the temperature under 60 degrees. Then we put glucose enzymes and PH reagent into these tanks. And after their chemical reaction, we will put the temperature above 90 degrees to kill glucose enzymes.

Decoloration and purifying system

2-a). The decoloration main function is to attract color, this step will be effect to the final product level, about 90% of colour will be attract inside the activated carbon, this parts the temperature is very important too. The press machines are used to remove the activated carbon.

2-b). For inox exchange system, we can use a heat-exchanger to make the temperature about 40 degrees.

Concentrating and storage system

glucose corn syrup processing lRead More

glucose syrup production plant from cassava pdf,glucose corn syrup processing line,glucose syrup making machine,production of glucose syrup f...

Introduction of Glucose syrup dRead More

Glucose syrup also known as confectioner's glucose, is a syrup made from the hydrolysis of starch. Glucose also is called starch sugar. Maize...

Annual capacity 50,000tons gluc

Annual capacity 50,000tons glucose syrup production plant, this capacity project our company totally installed three. Recently, we complete the third that is the newest glucose syrup production plant project

Read More

Daily production of 100 tons ma

This corn syrup production plant project all equipments design, manufacturer and delivery made by SIDA Company, with corn processing annual capacity 10 million tons, the corn syrup production capacity 8 million tons. Manufactured for our Nig

Read More

Phone669

Phone669

hoan366@hotmail.com

hoan366@hotmail.com