Production technology and complete processing equipment of syrups for industrial fermentation

This kind of beverage is also called soft drink, mainly refers to Coca Cola, soft drink, fruit juice, fruit juice, etc.High transparency, no turbidity, mild flavor, less irritation, no peculiar smell.

Used in alcoholic beverages

This category refers to fruit wine, fruit wine, wine, sparkling wine, champagne and so on processed with high fructose corn syrup.After pretreatment, the product can avoid precipitation, good transparency, when using high sugar preparation, honey taste is significant.It is easy to dissolve and dissolve, so it is convenient to use. For products requiring reducing sugar, the production process can be simplified (acid conversion is required for sucrose).

5.2 used for cold food

High fructose corn syrup is especially suitable for cold food due to its low temperature sweetness.If 5009 sucrose can be replaced by 5009 HFCS (non-dry matter), the product sweetness will not be affected.The production of Popsicle and ice cream with high fructose corn syrup can give it a delicate flavor.

5.3 for soft pastry and sandwich pastry

Fructose syrup is used in cakes, which are fluffy and soft after 30 days, while sugar cakes are dry and crumbly after a few days.

5.4 for fudge

Kaoliangyi, starch jelly, agarose and other soft products, reducing sugar content is high, water is more, in the past production need to use sucrose to add organic acids, one part of them into fructose and glucose.However, high fructose corn syrup does not need to be transformed and the product quality is better.

5.5 for canned fruit

The high osmotic pressure of high fructose corn syrup can penetrate the cell membrane wall of fruit quickly and equably, prevent the juice from going against the fruit, and help to maintain the fruit flavor.

5.6 used for preserves (preserves) and jams

Because of its high osmotic pressure, high fructose corn syrup can shorten the production cycle.Mixed with sucrose, the finished product is bright color;Used for jam, good preservative, good for storage.

5.7 application in medical care

Fructose and glucose can be absorbed directly by the body, so it is more beneficial for patients to use fructose syrup to process medical syrup. The product has good transparency and no impurities precipitation.

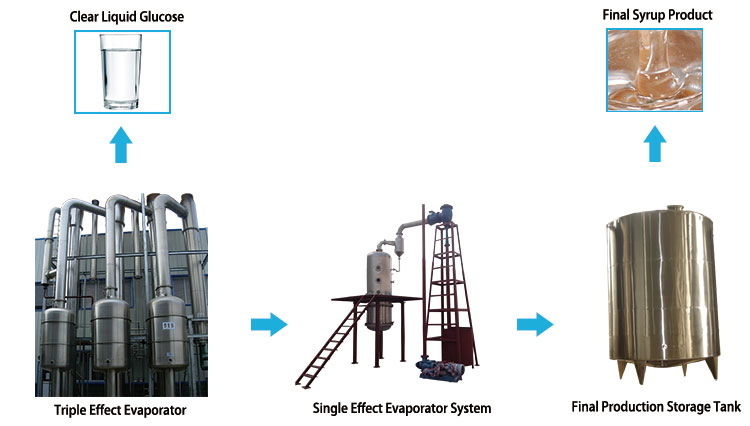

1) process flow

The acid process is shown in the figure:

Starch - mixing - saccharification - neutralization - first decolorization filtration - ion exchange -

First enrichment - second decolorization - filtration - second enrichment - finished product

Diagram acid process flow

2) operating points

(1) starch raw materials usually require high purity corn starch, followed by potato starch and sweet potato starch.

(2) mixing slurry in the mixing tank, first add some water, in the case of agitation, add crushed dry starch or wet starch, feed finished, continue to add 80℃ or so of water, so that the starch milk concentration reached 22 ~ 24 baume degree (glucose starch milk concentration of 12 ~ 14 baume degree), and then add hydrochloric acid or sulfuric acid to adjust the pH value of 1.8.Soft water is required to avoid the production of phosphate which makes the sugar liquid cloudy.

(3) the amylated starch milk is fed into the acid-resistant pressurized saccharification tank with acid-resistant pump.Steam starts while feeding, and after feeding, the pressure rises to (2.7 ~ 2.8)×104pa(temperature 142 ~ 144℃), 0 for each boost in the boost process.98×104pa, about 0.The cold air is expelled for 5 min, which is closed when the white smoke is discharged, and then the saccharification mash is agitated and heated evenly. When the pressure rises to the required pressure, the DE value is kept for 3-5 min, and the DE value is measured by sampling in time. When the DE value reaches 38-40, the saccharification is terminated.

(4) after the neutralization and saccharification, open the saccharification pot and introduce the saccharification liquid into the neutralization barrel for neutralization.Hydrolyzed with hydrochloric acid, neutralized with 10% sodium carbonate, or hydrolyzed with sulfuric acid, neutralized with calcium carbonate.The calcium chloride produced by the former is dissolved in the sugar solution, but the quantity is not large, which has little impact on the flavor. The calcium sulfate produced by the latter can be removed during filtration.

The purpose of neutralization in saccharification liquid is not to neutralize the pH value of 7 at the real neutralization point, but to neutralize most hydrochloric acid or sulfuric acid, adjust the pH value to the freezing point of protein, make protein coagulation and filtration remove, and keep the sugar liquid clear.The best pH for protein coagulation in sugar solution is 4.75, so it's generally neutralized to a pH of 4.6 to 4.8 is the neutralization end point.When neutralizing, add dry matter mass 0.The clarification agent was 1% diatomite, which was dispersed in aqueous solution with negative charge, and the protein in acidic medium with positive charge, so the clarification effect was very good.

(5) decolorization filtration neutralizes sugar liquid cooling to 70 ~ 75℃, adjust pH value to 4.5. Add powdered activated carbon with a mass of 0· 25%, stir with adding for about 5 min, press plate frame filter press or horizontal closed drum leaf filter press to filter the filtrate of sugar.

(6) the sugar solution filtered by the first decolorization was desalinated and purified by four ion exchange columns of Yang - Yin - Yang - Yin.

(7) adjust the pH value of purified sugar solution to 3 after the first concentration.8 ~ 4.2. Pump into the evaporation tank to keep the vacuum degree above 66.661 Pa, and the heating steam pressure shall not exceed 0.98 by 10.Pa, concentrate to 28 ~ 31 baume degree, discharge, conduct the second decolorization.

(8) the second decolorization filter the second decolorization is the same as the first one.The second decolorizing syrup must be repeatedly reflux filtration until there are no activated carbon particles, and then adjust the pH value to 3.8 ~ 4.2.

(9) the second concentration is the same as the first concentration, except that sodium bisulfite is added before the concentration, so that the content of sulfur dioxide in the sugar solution is 0.0015% ~ 0.004% for bleaching and color protection.Evaporation to 36 ~ 38 baume degree, out, that is the finished product.

2. Acidase process

Because the acid process is difficult to control in the degree of hydrolysis, many factories now use acidase method, that is, acid method liquefaction, enzymatic saccharification.During acid liquefaction, the hydrolysis reaction is controlled so that the DE value stops at 20% ~ 25% and neutralizes rapidly.Adjust pH to 4.About 5, after the temperature is 55 ~ 60℃, glucose amylase is added for saccharification until the required DE value, and then the temperature is raised, enzyme is destroyed, decolorization, ion exchange and concentration.

3. Double-enzyme process

Although the acidase process can better control the final DE value of saccharification liquid, it still has some shortcomings, just like the acid method. The equipment is corroded seriously, so the raw material can only be limited to starch, and there are many by-products generated in the reaction, and the final syrup is not pure sweet taste. Therefore, most starch sugar manufacturers use the enzymatic production process.Its biggest advantage is that liquefaction, saccharification are enzymatic hydrolysis, reaction conditions are mild, almost no corrosion to the equipment;Can directly use raw grains such as rice (broken rice) as raw materials, is conducive to reducing production costs, sugar liquid purity is high, high yield.

glucose corn syrup processing lRead More

glucose syrup production plant from cassava pdf,glucose corn syrup processing line,glucose syrup making machine,production of glucose syrup f...

Introduction of Glucose syrup dRead More

Glucose syrup also known as confectioner's glucose, is a syrup made from the hydrolysis of starch. Glucose also is called starch sugar. Maize...

Annual capacity 50,000tons gluc

Annual capacity 50,000tons glucose syrup production plant, this capacity project our company totally installed three. Recently, we complete the third that is the newest glucose syrup production plant project

Read More

Daily production of 100 tons ma

This corn syrup production plant project all equipments design, manufacturer and delivery made by SIDA Company, with corn processing annual capacity 10 million tons, the corn syrup production capacity 8 million tons. Manufactured for our Nig

Read More

Phone669

Phone669

hoan366@hotmail.com

hoan366@hotmail.com