Broken rice glucose syrup processing machine

Processing Capacity : 10-300tons/24 hoursApplication Scope : Broken rice transformed into glucose syrup

WhatsApp : Phone669

Email : hoan366@hotmail.com

Phone : Phone669

hoan366@hotmail.comleave message

Glucose syrup, also known as confectioner's glucose, is a syrup made from the hydrolysis of starch. Maize (corn) is commonly used as the source of the starch in the US, in which case the syrup is called "corn syrup", but glucose syrup is also can be produced from potatoes starch , wheat starch , rice starch and cassava starch.

The traditional method is produce glucose syrup from the starch . Now our company has the new technology , we can produce glucose syrup from maize (corn) or broken rice directly . It does not need making the starch first.

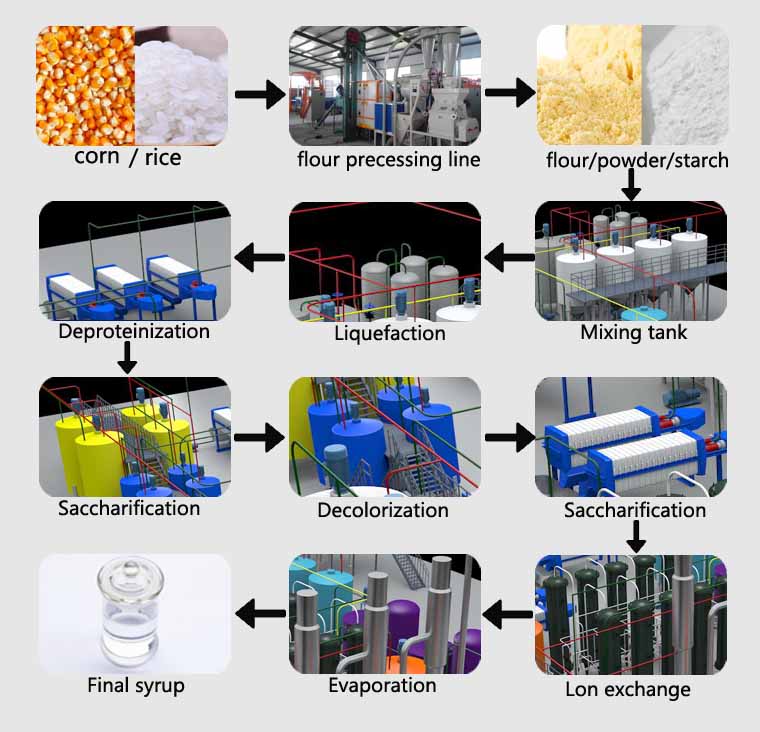

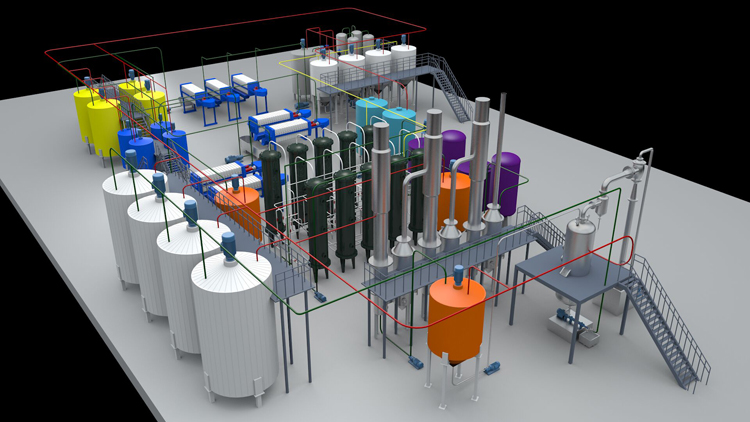

Our company technology for the rice glucose syrup processing plant is as below :

Broken rice glucose syrup process

1. Rice powder making process in rice glucose syrup processing machine

The Broken rice must be cleaned to ensure the broken rice without any purity before enter into the milling machine. Then milling the cleaned broken rice to powder form, after sieving and milling some times to get the required rice powder for making rice glucose syrup.

2. Rice power slurry making process in rice glucose syrup processing machine

Mixing the rice powder and water to get the right density slurry. Then add the amylase and keep on the temperature for particular time to make rice powder absorbing enough water .

3. Liquefaction process in rice glucose syrup processing plant

The liquefaction process is convert the starch which contented inside of the rice powder into liquid dextrin. The material will be sprayed at high temperature by jet cooker . With the aid of amylase and steam , the starch will be converted into liquid dextrin quickly.

4. Deproteinization process in rice glucose syrup processing machine

The deproteinization process is separate the rice protein and other solid impurity from liquid dextrin by filter press. The liquid dextrin will be pumped to next process, the rice protein will be left for sale. .

The by product rice protein ( feed grade) is top grade protein additives for making animal feed .

5. Saccharification process in rice glucose syrup processing machine

The saccharification process is convert the liquid dextrin into required DE value glucose syrup with the aid of gluco-amylase in the tank . This process should be run under specific temperature for some hours . This process is get the crude and yellow color glucose syrup.

6. Decolorization process in rice glucose syrup processing machine

The decolorization process is removing the color of the glucose syrup by activated carbon. The glucose syrup which reached required DE will be pumped from saccharification tank into the decolorization tank , mixed with activated carbon at proper temperature .

7.Decarburization process in rice glucose syrup processing machine

The decarburization process is separating the activated carbon from the glucose syrup by filter press to get clear glucose syrup.

The glucose syrup will flow into the slot and the transfer tank for next step. The activated carbon will be left.

8. Ion exchange process in rice glucose syrup processing machine

The Ion exchange process is using the resin to remove the tiny foreign items and bad odor to get high quality pure glucose syrup.

The resin need regeneration by acid and alkali washing after working for some days

9. Evaporation process in rice glucose syrup processing machine

The evaporation process is evaporate the water inside the glucose syrup to increase the DS of glucose syrup.

Usually it need multi-effect evaporator work together with the single effect evaporator for producing high DS glucose syrup.

10. Final product storage in rice glucose syrup processing machine

The glucose syrup which reach the required DS in the evaporation process will be pumped into final product storage tanks for storage.

The final product tank can keep the glucose syrup purity before transportation.

Broken rice glucose syrup processing machine

glucose corn syrup processing lRead More

glucose syrup production plant from cassava pdf,glucose corn syrup processing line,glucose syrup making machine,production of glucose syrup f...

Introduction of Glucose syrup dRead More

Glucose syrup also known as confectioner's glucose, is a syrup made from the hydrolysis of starch. Glucose also is called starch sugar. Maize...

Annual capacity 50,000tons gluc

Annual capacity 50,000tons glucose syrup production plant, this capacity project our company totally installed three. Recently, we complete the third that is the newest glucose syrup production plant project

Read More

Daily production of 100 tons ma

This corn syrup production plant project all equipments design, manufacturer and delivery made by SIDA Company, with corn processing annual capacity 10 million tons, the corn syrup production capacity 8 million tons. Manufactured for our Nig

Read More

Phone669

Phone669

hoan366@hotmail.com

hoan366@hotmail.com